Food contamination can lead to devastating consequences, such as illness outbreaks and product recalls, which can cause irreparable damage to a company’s reputation. That’s why understanding the HACCP steps is essential for anyone working in food production, processing, or quality control.

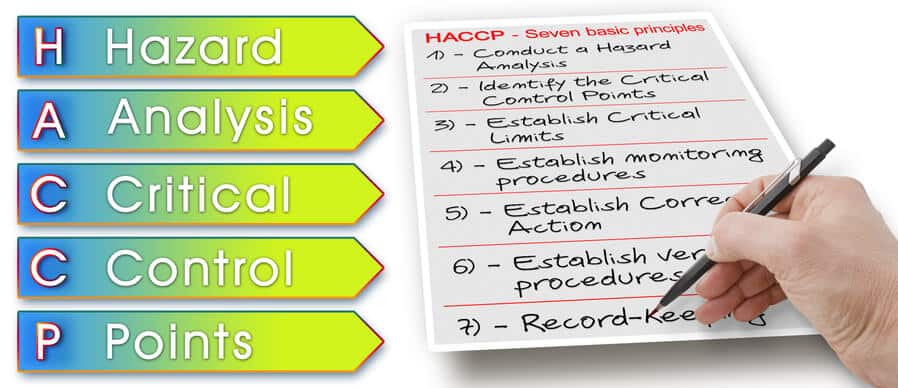

HACCP (Hazard Analysis and Critical Control Points) is a globally recognized system designed to proactively identify, evaluate, and control food safety hazards at every stage of the supply chain. Rather than relying on end-product testing alone, HACCP ensures food safety is baked into the process, reducing risk before it reaches the consumer.

For students and aspiring professionals enrolled in our food safety course, mastering the seven HACCP steps is a career-defining skillset. These principles are key to regulatory compliance as well as to building a successful, safety-first mindset in today’s competitive food industry. This blog post highlights each step and explains how you can apply them effectively with the right training.

1. Conduct a Hazard Analysis

The first step involves identifying all potential hazards, biological, chemical, or physical, that could affect food safety at each stage of your process. This includes everything from raw material sourcing to distribution. For example, bacterial contamination during handling or cross-contamination from equipment can pose serious risks.

Students in a food safety course learn to use flow diagrams and risk assessment tools to systematically evaluate these dangers. Understanding the specific risks in your production line allows you to plan controls and interventions proactively.

Students in a food safety course learn to systematically evaluate dangers.

2. Identify Critical Control Points (CCPs)

Once hazards are identified, the next step is to pinpoint Critical Control Points, the stages in the process where you can apply controls to eliminate or reduce the hazards to acceptable levels.

Common CCPs include cooking, chilling, and packaging steps. For instance, a thermal processing step that kills bacteria would be considered a CCP. Learning how to recognize these points is a core skill covered in the food safety and quality program at AAPS.

3. Establish Critical Limits

For each CCP, you must define a critical limit, such as a specific temperature, pH level, or time requirement, that must be met to ensure the hazard is controlled. These limits are often based on regulatory standards or scientific research.

In AAPS’ food safety course, you’ll learn the importance of monitoring temperature data.

4. Monitor the CCPs

Once critical limits are set, it’s important to monitor them. Monitoring can be continuous (e.g., automatic temperature sensors) or periodic (e.g., manual testing).

In AAPS’s hands-on training environment, students practice using various monitoring techniques and instruments.

5. Establish Corrective Actions

If a CCP is not within its critical limits, you must act fast. Corrective actions are pre-planned steps to regain control and address any affected product. Effective corrective actions prevent unsafe products from reaching consumers and are essential for regulatory audits.

6. Establish Verification Procedures

Verification ensures that your HACCP plan is working as intended. This might include reviewing records, calibrating instruments, or conducting microbiological testing.

In the food safety course, students learn how to design robust verification strategies. Without this step, you risk relying on a plan that might not adequately protect public health.

7. Maintain Documentation and Records

Finally, accurate and accessible documentation is key. Records of hazard analyses, CCP monitoring, corrective actions, and verification activities provide the traceability.

Documentation is another key skill you’ll master in food safety training.

Why HACCP Training Matters

Implementing these seven HACCP steps is about ensuring trust, transparency, and safety in the food supply chain. Whether you aim to work in food production, QA, or regulatory affairs, having a solid command of HACCP is vital.

Through AAPS’s comprehensive Food Safety and Quality Program, you’ll gain the technical knowledge and practical experience to lead HACCP implementation with confidence. From lab-based projects to real-world case studies, AAPS prepares students to meet the evolving demands of the food industry.

Are you looking for a comprehensive Food Safety and Quality program?

Contact AAPS for more information.