Quality departments within the cannabis market are responsible for conducting and monitoring activities that affect the quality, safety, or efficacy of cannabis products. Related to this area, ultrasonic energy has a number of uses in both cannabis testing and production labs. Ultrasonic energy has long been an excellent method of cleaning lab equipment and removing contaminants from virtually any product, but it can be used in several ways to ensure that a cannabis product is of the highest quality.

For that reason, many cannabis businesses today are turning to ultrasonic energy to extract and process their cannabis products. For those studying cannabis quality assurance, read on to discover how ultrasonic energy is applied to the field!

Exploring Ultrasonic Energy in Cannabis Quality Assurance

Generally, ultrasonic energy is defined as sound above the range of human hearing – approximately 20Hz – and is commonly associated with cleaning. Ultrasonic extractors use ultrasonic waves to push a product out through vibration, eliminating the need for solvents. The ultrasonic vibrations cause microscopic bubbles to form, which implode to loosen any stubborn contaminants. This process is highly effective on even the most fixed residue.

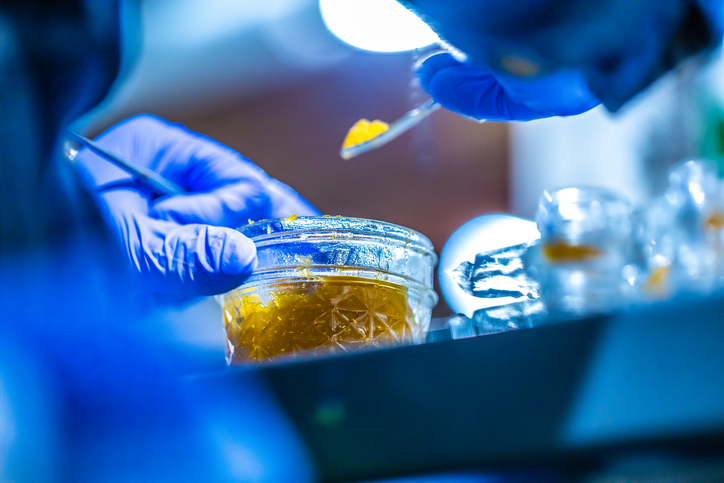

While ultrasonic energy is historically used as a cleaning tool, in recent years cannabis labs have been applying ultrasonic cleaners to refine their cannabis products. By vibrating a cannabis product at a specific frequency, ultrasonic energy can be used for:

- Extraction procedures

- Preparing oil emulsions for edible products

- Degassing oil to ensure stable oil volume for sales

- Bubbling off ethanol before oil distillation

Those interested in cannabis quality assurance careers should explore the potential of ultrasonic energy for ensuring quality and efficiency during cannabis production.

Ultrasonic technology can be used to prepare oil emulsions for edible products

How Ultrasonic Energy Can Benefit Cannabis Quality Assurance

Cleaning both the interior and exterior of cannabis processing equipment is necessary for ensuring the quality of the product, as well as upholding the investments made in glassware and other lab equipment. When it comes to cannabis quality assurance, ultrasonic systems are highly effective in removing waxy residues and contaminants from extraction equipment. This allows producers to:

- Shorten extraction times

- Increase yield output

- Eliminate the need for manual scrubbing

- Streamline the cleaning of cannabis equipment

Ultrasonic energy is a highly effective method of cleaning gums and waxes from glassware

Generally, labour is one of the most costly aspects of the cleaning process. Beyond being a highly effective method of cleaning gums and waxes from glassware, ultrasonic cleaning systems offer significant financial benefits for cannabis producers by allowing them to cut labour costs. Additionally, ultrasonic energy offers a much safer cleaning method by relying on water-based detergents. This eliminates the use of toxic solvents in the workplace, reducing the risk of contamination costs and personnel exposure to toxic chemicals.

Ultrasonic cleaning can allow cannabis producers to cut labour costs

Things to Consider For Those in a Cannabis Course

With the legalization of cannabis in full swing, industry professionals must look to the future and consider ways to improve their production processes. A cannabis quality assurance course teaches students the fundamentals of good production practices, relating to the premises, equipment, sanitation, and quality inspection. Having effective cleaning procedures and using their procedures effectively will minimize the risk of contamination, return of products, and recalls. An ultrasonic energy system not only maximizes the degree to which cannabis production equipment and tools are cleaned, but it also delivers a safer, timely, and cost-efficient method.

Ready to launch your career with a cannabis course?

Start your training with the Academy of Applied Pharmaceutical Sciences!